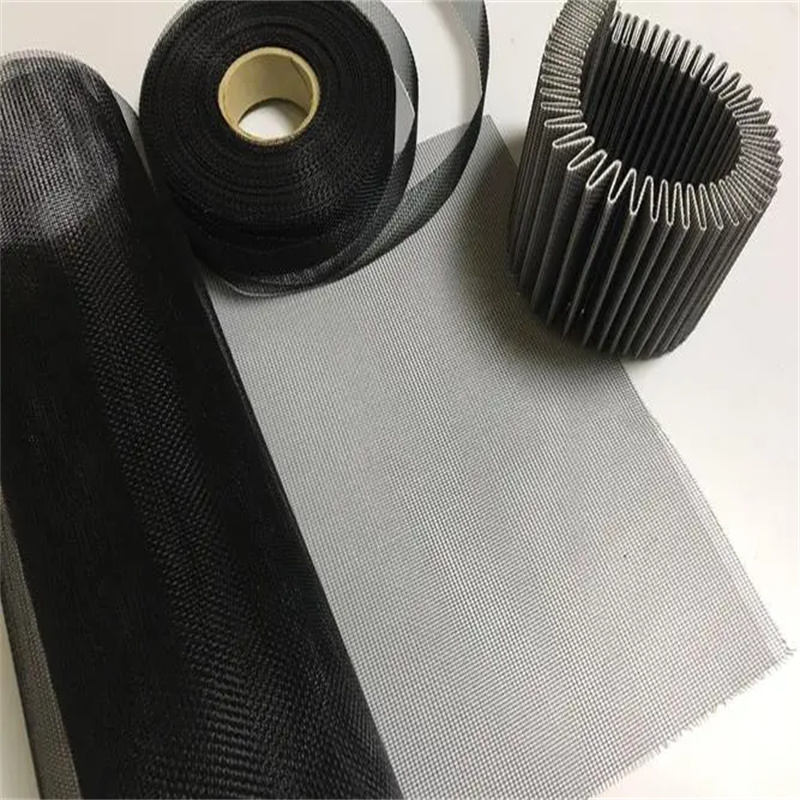

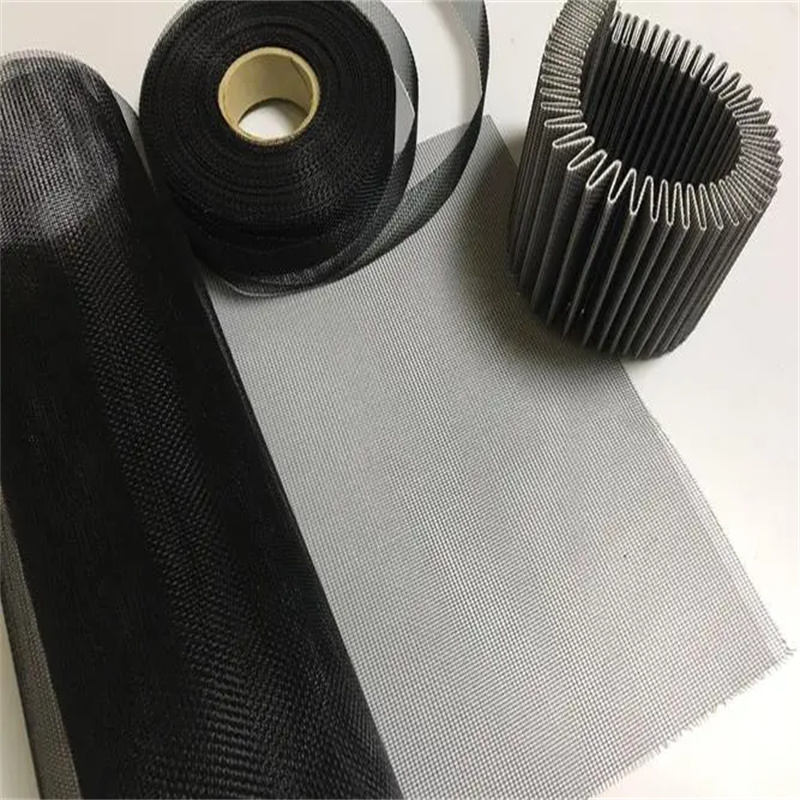

Epoxy-coated wire mesh is mainly used in filters for several applications due to its enhanced properties and durability. Here we introduce you some key uses and benefits of epoxy-coated wire mesh in filters:

Uses of Epoxy-Coated Wire Mesh in Filters

-

Air Filters:

-

HVAC Systems: Epoxy-coated wire mesh is often used in HVAC systems to trap dust, pollen, and other airborne particles. The coating helps prevent corrosion, ensuring a longer lifespan even in humid environments.

-

Industrial Air Purifiers: In industrial settings, these filters help clean the air by capturing fine particles, including smoke, dust, and chemical fumes.

-

Water Filters:

-

Potable Water Treatment: Epoxy-coated wire mesh is used in filters to remove contaminants from drinking water. The coating ensures that the mesh does not corrode or degrade over time, maintaining water quality.

-

Wastewater Treatment: In wastewater treatment plants, these filters help in the initial stages of separating solids from liquids, protecting the integrity of the filtration system.

-

Oil and Fuel Filters:

-

Automotive and Machinery: Epoxy-coated wire mesh is used in oil and fuel filters for vehicles and machinery. The coating prevents the mesh from reacting with the oils and fuels, thus extending the filter's life.

-

Industrial Equipment: These filters are also used in various industrial machines to remove contaminants from lubricants and hydraulic fluids.

-

Food and Beverage Industry:

-

Ingredient Filtration: Epoxy-coated wire mesh filters are used to ensure the purity of ingredients in food and beverage production, preventing contamination from rust or mesh degradation.

-

Process Water Filtration: Ensuring clean water for food processing, which is crucial for maintaining hygiene and product quality.

Benefits of Using Epoxy-Coated Wire Mesh in Filters

-

Corrosion Resistance: The epoxy coating protects the wire mesh from rust and corrosion, which is particularly important in moist or chemically aggressive environments.

-

Durability: The coating adds a layer of protection that extends the lifespan of the mesh, making it more resistant to wear and tear.

-

Chemical Resistance: Epoxy coatings can resist a variety of chemicals, making the mesh suitable for use in diverse industrial applications where chemical exposure is common.

-

Enhanced Performance: The smooth surface of the epoxy coating can improve the flow of air or liquids through the mesh, enhancing the efficiency of the filtration process.

-

Cost-Effectiveness: By extending the lifespan and reducing the need for frequent replacements, epoxy-coated wire mesh can be a more cost-effective solution in the long run.

Conclusion

Epoxy-coated wire mesh is a versatile and durable material used in various types of filters. Its corrosion resistance, durability, and chemical resistance make it suitable for demanding applications in air and water filtration, oil and fuel filtering, and the food and beverage industry. The enhanced performance and extended lifespan provided by the epoxy coating ensure that these filters remain effective and reliable over time.